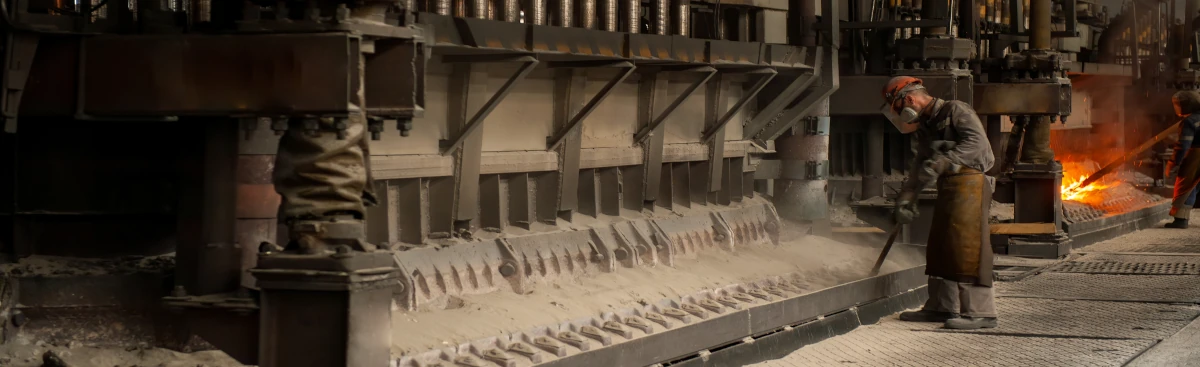

The secondary aluminum industry plays a crucial role in our modern world, providing lightweight, recyclable material for countless applications. Yet, lurking within every smelter is a significant hazard that is often underestimated: the risk of dust explosions due to aluminum dust. As the industry seeks to improve safety, sustainability, and efficiency, addressing this danger has become more important than ever.

Why Aluminum Dust Explosions Are So Dangerous

Aluminum dust, especially in its ultrafine form, is highly combustible. When suspended in the air in sufficient concentrations, aluminum dust can create an explosive atmosphere. All it takes is an ignition source—a spark from a tool, static electricity, or an overheated machine—to trigger a chain reaction with devastating consequences. Aluminum dust explosions can occur with a force comparable to dynamite, endangering lives, causing severe damage to infrastructure, and leading to costly downtime.

A recent case study vividly demonstrates the catastrophic effects of an aluminum dust explosion due to insufficient dust management. This case study, available in the video linked below, illustrates how a lack of proper precautions and maintenance of dust collection systems led to severe consequences:

Factors Contributing to Aluminum Dust Explosion Risks

Several factors make this threat particularly pressing. Aluminum is a highly reactive metal; it oxidizes rapidly when finely divided, releasing a tremendous amount of energy. When dust accumulates in poorly ventilated or confined spaces, the risk of an aluminum dust explosion increases dramatically. Processes such as grinding, material transport, and scrap handling generate fine and ultrafine aluminum dust that can become airborne if not properly controlled.

Effective Dust Management Strategies

Effective dust management is critical to minimizing these aluminum dust explosion risks. The industry has made significant progress in developing solutions to mitigate dust-related dangers. Dust collection systems like baghouses and electrostatic collectors are becoming more prevalent, capturing particles before they can accumulate in the air. Moreover, advanced vacuum systems are being used to collect even the finest particles without creating harmful dust clouds, thereby reducing the likelihood of dangerous conditions forming within smelters.

The Importance of Worker Education in Reducing Aluminum Dust Explosion Risks

In addition to technological solutions, worker education is essential. Employees must understand the explosive potential of aluminum dust and the importance of proactive dust management. Regular maintenance, proper equipment calibration, and effective cleaning systems are all key components of an effective safety strategy.

Opportunities for Safety and Sustainability

Aluminum smelters have an opportunity not only to improve safety but also to lead the way in sustainable practices. By capturing and recycling aluminum fines, smelters can reduce waste, recover valuable materials, and lower their environmental impact. Implementing these strategies makes it easier for smelters to achieve their safety and sustainability goals while simultaneously improving operational efficiency.

Comprehensive Approach to Mitigate Aluminum Dust Explosion Risks

Mitigating aluminum dust explosion risks requires a comprehensive approach: effective dust collection, consistent monitoring, worker training, and sustainable dust recycling. By embracing these strategies, secondary aluminum processing facilities can continue to innovate and grow, while keeping workers safe and operations secure.

To explore more in-depth insights and strategies on managing aluminum dust and ultrafine dust risks in secondary aluminum processing environments, download our comprehensive whitepaper today. Gain access to detailed information on best practices, technologies, and actionable steps to maximize safety and efficiency in your operations.

Download the white paper

Together, let’s propel the aluminum industry forward, paving the way for a future where innovation, sustainability, and progress go hand in hand. Download our white paper now and be part of the movement that shapes a brighter tomorrow.